Questioning the Limits of Textile Efficiency: The SFZJ600 Full Plasma Winding Machine

In the textile industry, efficiency, precision and quality have become the key indicators to measure the performance of equipment. As a leader in the ...

Read MoreScope of application:

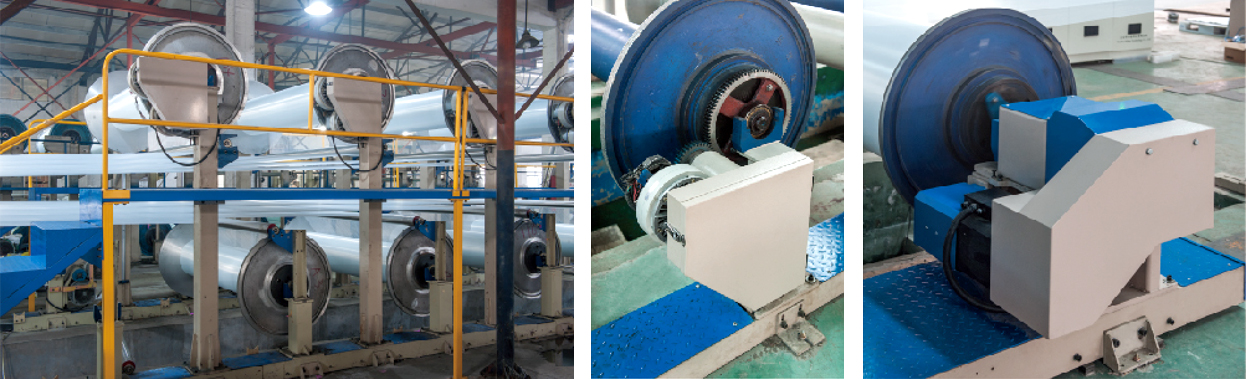

This series of models can process a plurality of pulp (warp) shafts processed by batch warping machines, sizing machines and sizing machines and combine them into woven shafts.

Coil part:

· The upper and lower shafts of the hydraulic support arm are opened and closed by an electric beater, making it easier to load and unload the weaving shaft.

· Wrapped design, 3 infrared safety protection devices, safer operation.

· Adopt high-end frequency converter, constant tension closed-loop automatic control, more stable operation.

Decommissioning parts:

· The paddle shaft is put into the working position, and the operation is more convenient with the clutch device.

· Servo motor retreat: stable operation and high control precision.

· With power failure protection.

· Each pedestal can be optionally equipped with spreader rollers. (Customer purchase) Each axle frame is equipped with a brake device.

· Each axle frame has tension closed-loop automatic control.

· It can be used to process the paddle shafts with different auxiliary diameters at the same time.

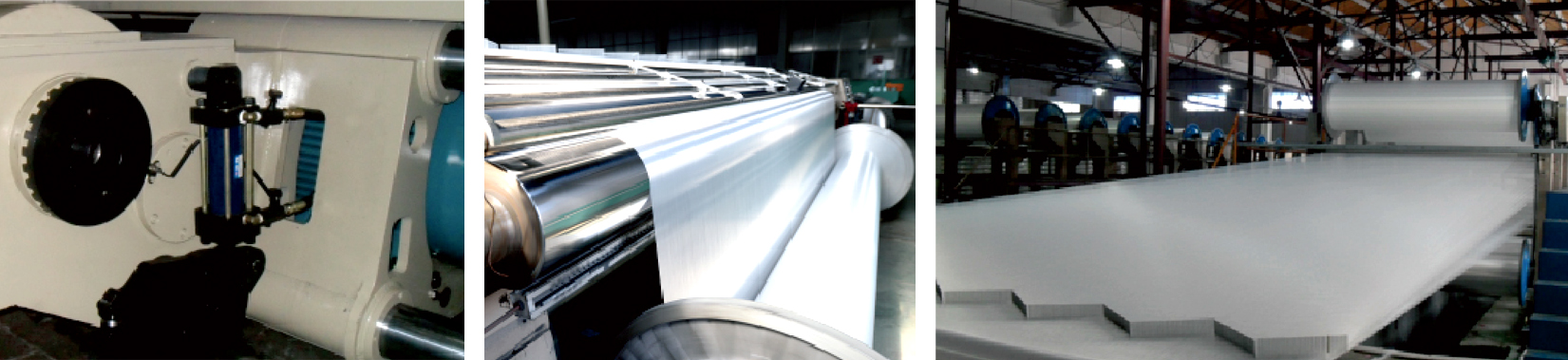

Coil part:

· Adopt oil bath large modulus helical gear transmission to make the transmission more stable and quiet.

· The use of hydraulic support or hydraulic lifting platform up and down shafts (customer choice) and electric flap opening and closing forms make the weaving shaft loading and unloading simple and convenient.

· Adopt four-roller drive, equipped with anti-rotation device, keep the tension of the silk sheet when the machine is stopped.

· Using pressure sensor control technology, the coiling tension is more stable.

· The taper tension is automatically controlled by the frequency conversion motor.

· Equipped with infrared safety protection device to ensure safe operation.

· Equipped with electric telescopic foil left and right movement and rescue expansion device.

· Equipped with telescopic i-lifting device.

· Optional static elimination device.

Control parts:

· Adopt advanced PLC control system and frequency conversion control mode to ensure operation under constant line speed and constant tension.

· Using touch screen control, the display is clearer and the operation is more convenient.

· Multi-camera control button to ensure easy to use, safe and reliable.

· Equipped with a power failure protection system, abnormal power failure can also ensure the safety of the silk.

| Top speed | 150 mImin | 300 m /min | ||

| The number of Warp Beaming | 3 - 24 | |||

| The Tensions Range of Coiling | 180 KG - 1500 KG | |||

| The Working Width | 2300mm | 2800mm | 3200mm | 3600mm |

| The Diameter of weaver's beam | Φ800 mm Φ900mm Φ1000mm |

|||

| The Adjustment Way of telescopic reed | Electric Adustment | |||

| The load and unload Form of weaver's Beam | Hydraulic bracket or hydraulic lifting platform(Customer selection) | |||

| The Control Mode of Coiling Tension | Automatic Control by Magneic Powder Brake/Motor automatic control | |||

| The Control Form of Uwinding Tension | Automatic Control by Frequency Conversion motor | |||

| The Control Form of Taper Tension | The Control Mode for tension Feedback for AC Vector | |||

| Drivinq mode | Single motor drive | Duble motor drive | ||

| The Form of Unwinding Beam Bracket | Single layer bracker | Duble fayer bracker | ||

| The Expanding filament guide Roller | The width is 3600mm,each beam is equipped one | |||

| Display System | Touch-operated Displays | |||

| The Eloclrical Assembly | 30-70 KVA | |||

Suzhou Sifang Technology Co., Ltd. is China beaming machine manufacturers and SFB300 Type Beaming Machine factory with more than 30 years of experience.

The company has more than 100 employees. As a professional manufacturer of SFB300 Type Beaming Machine. It has excellent processing and metal cutting equipment, as well as excellent design and development personnel, and high-quality employees team, and a strong quality management system.

The products are exported to many countries, with a total of seven sales outlets and sales of over 100 million US dollars.

The company's existing professional production machinery and equipment, production and supply of various series of products: SFZ700 series warping machine, SFJ600 series pulp wire, SFZJ600 series sizing machine, SFB300 series parallel axis machine, SFJ100 series drying drum pulping machine.

In particular, we always research and provide individual solutions according to the needs of our customers, and we make special customizations. Suzhou Sifang Technology Co., Ltd. has more than 6,000 square meters of modern workshops and other world-leading hardware; equipped with advanced processing systems. Realize mass production and partial assembly line operation.

Service Capability: In order to establish and enhance the popularity of Sifang Technology brand in overseas markets, we always adhere to the corporate culture of "Honesty, being a man, breaking into the world Team work goes all way", focus on developing and expanding the sales service center, and focus on SFB300 Type Beaming Machine product quality , to ensure product after-sales.

Our team of digital and business experts will guide you to the right direction.

Let's TalkIn the textile industry, efficiency, precision and quality have become the key indicators to measure the performance of equipment. As a leader in the ...

Read MoreWith the rapid development of the textile industry, efficient and accurate warping equipment has become the key to improving production efficiency and...

Read More